Not Available in The US

This product is no longer offered by Intepro Systems in the United States. Should you need technical assistance, we will continue to support our products through our support section.

This product is no longer offered by Intepro Systems in the United States. Should you need technical assistance, we will continue to support our products through our support section.

Each module is 320W that allows for a 3200W total in the 10 channel chassis with a voltage up to 200V. The 10 channels are independently controlled but require the rack as it contains the energy recovering DC-AC inverter. The modules are also extendable and parallel connection on the DC inputs of the module is a function of the assembly.

Ethernet/LAN interface built-in to DC Load

FRONT PANEL

The load modules come in two voltage variants, 80 V and 200 V, and incorporate the common regulation modes, constant voltage (CV), constant current (CC) and constant power (CP). Both modules have a max. power of 320 W, while the 80 V module can take up to 25 A and the 200 V module can take up to 10 A. By installing up to 10 units of these load modules into a single rack it is possible to extend the power to 3200 W max.

The LCD touch panel offers a modern and intuitive user interface for controlling the four operating modes, Constant Voltage (CV), Constant Current (CC), Constant Power (CP) and Constant Resistance (CR).

Equipped with an Ethernet port by default, the ELR 5000 load units can be easily integrated into a network of LAN devices. External control is possible via an included Windows software package or via custom applications created in LabView or other IDEs. The commonly known communication protocols SCPI and ModBus are supported.

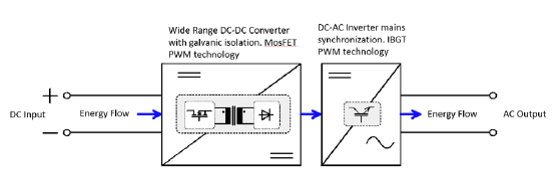

The energy recovery function inverts the supplied DC energy into a synchronous sine wave current and feeds it back into the local grid. This reduces the usual heat dissipation to a minimum and saves energy costs at the same time. This important feature of these electronic loads is that the AC input, i.e. grid connection, is also used as output for the recovery of the supplied DC energy, which will be converted with an efficiency of approximately 90%. This way of energy recovery helps to lower energy costs and avoids expensive cooling systems, such as required for conventional electronic loads which convert the DC input energy into heat.