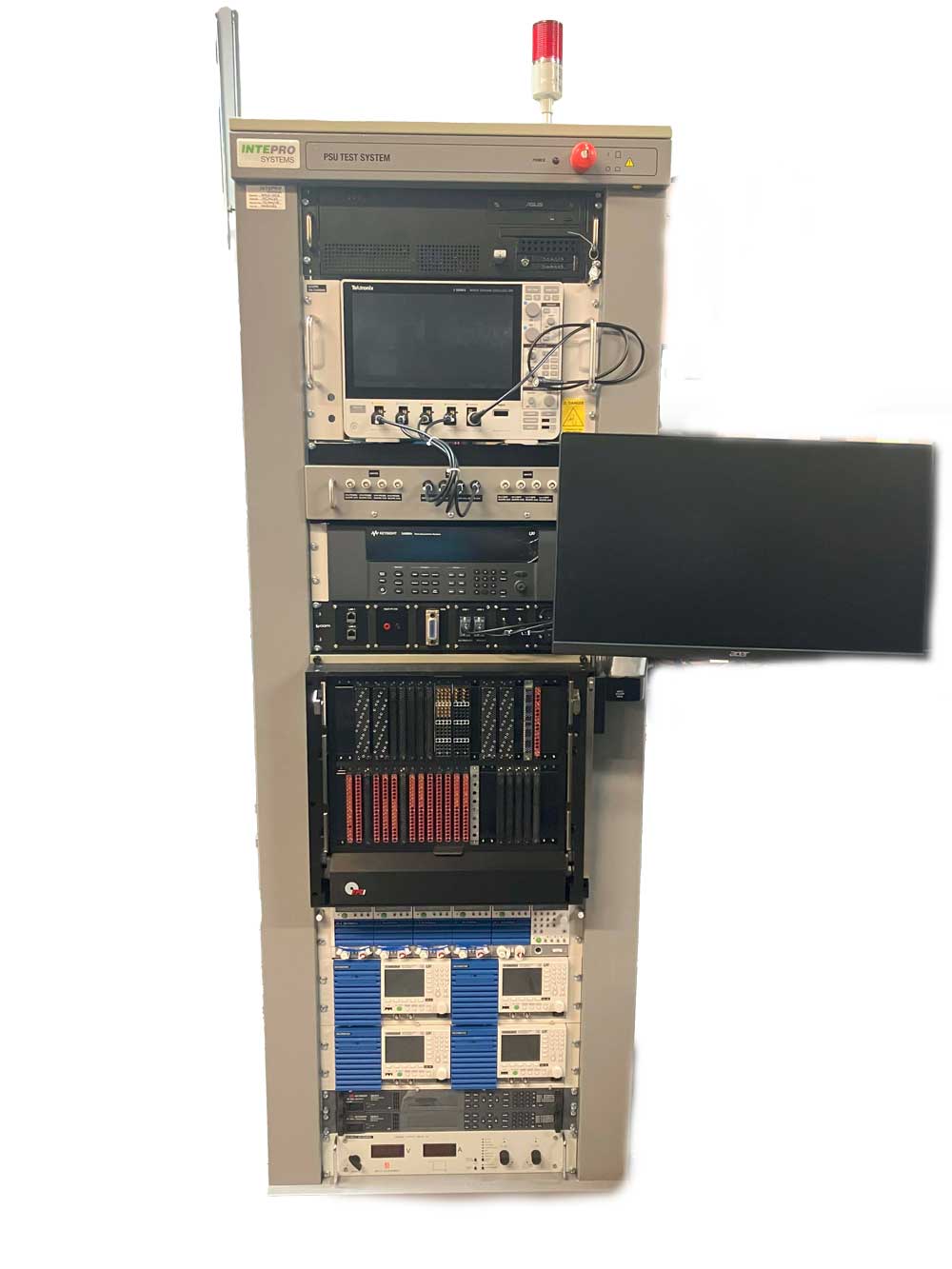

Battery Test Systems

Combining high resolution, high powered charge and discharge systems, Intepro IBT line of battery test systems link to the battery management through the bus communication and fail-safe external monitoring of key battery parameters.

The Intepro IBT battery test system includes the PowerStar test executive making the system ideal for characterization, production or depot test. Systems are scalable for single or multiple batteries. Test results may be logged for future analysis and the system can also perform data transmission and interrogation of intelligent systems.

Key Features

- 60V for Vehicle Systems: Up to 60V operation allows the simulator to be used for 12V, 24V, and 42V vehicle systems

- Continuous Operation: 16KW continuous operation without any external cooling required

- Battery Testing: Decaying Battery Tests

- Voltage Testing: Fast dips and dropouts

- Battery Cranking Tests: Simulate real life battery conditions

Battery Simulator Test System

Battery simulators replace the vehicle battery in the test environment. The simulator fulfills various test criteria’s concerning power rating, voltage, slew-rate, impedance, etc. depending on the particular application. The B2010 is a programmable DC Source similar to a power amplifier which has been designed for use within the automotive industry. With its very low output impedance, it is an ideal battery simulator. The voltage sensing circuitry within the amplifier helps to regulate the voltage, thus keeping the apparent output impedance even lower.

The simulator can be programmed manually or driven by an arbitrary signal to simulate real-life battery conditions. A 0 – 6v differential input signal can control the 0 – 60v output voltage.

Request a Quote Today

FAQ

Intepro Battery Test System is a configurable ATE solution especially the Procyon IBT line designed for testing Lithium-ion and other high-power-density batteries and chargers, capable of high-resolution, high-power charge/discharge cycles.

Products

Support

Company